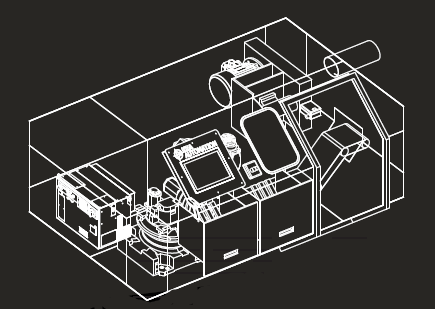

Utalising Fanuc robot technology, automatic programs ensure repeatedly and accuracy of the cutting operation. Automatic pneumatic clamp actuation with bespoke tooling securely holds the tree for manipulation during operations.

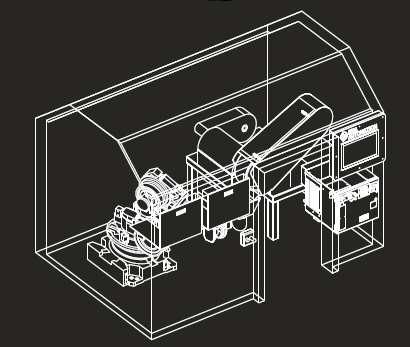

The cutting and grinding solutions are scalable and can be tailored to all casting sizes.

Dynamic pressure control technology ensures an even cutting pressure at all times that extends the blade or belt life Laser controlled wheel disc wear level monitoring provides automatic notification when replacement is required.

Enhanced operator control using the cut-off and grinding management system softawre allows the process monitoring and data recording.